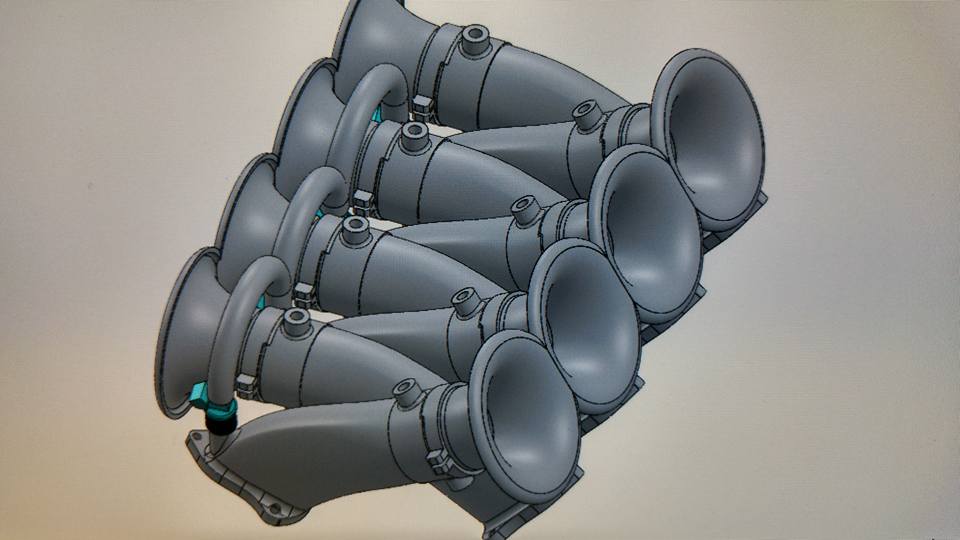

I've started casting some prototype ITB's for cathedral port LSX motors.

|

Cathedral port junkyard LS motors are being swapped into everything these days. I decided to put my spin on a set of billet individual runners. I'm currently modelling the stock ports to see where they could benefit from some simple mods.

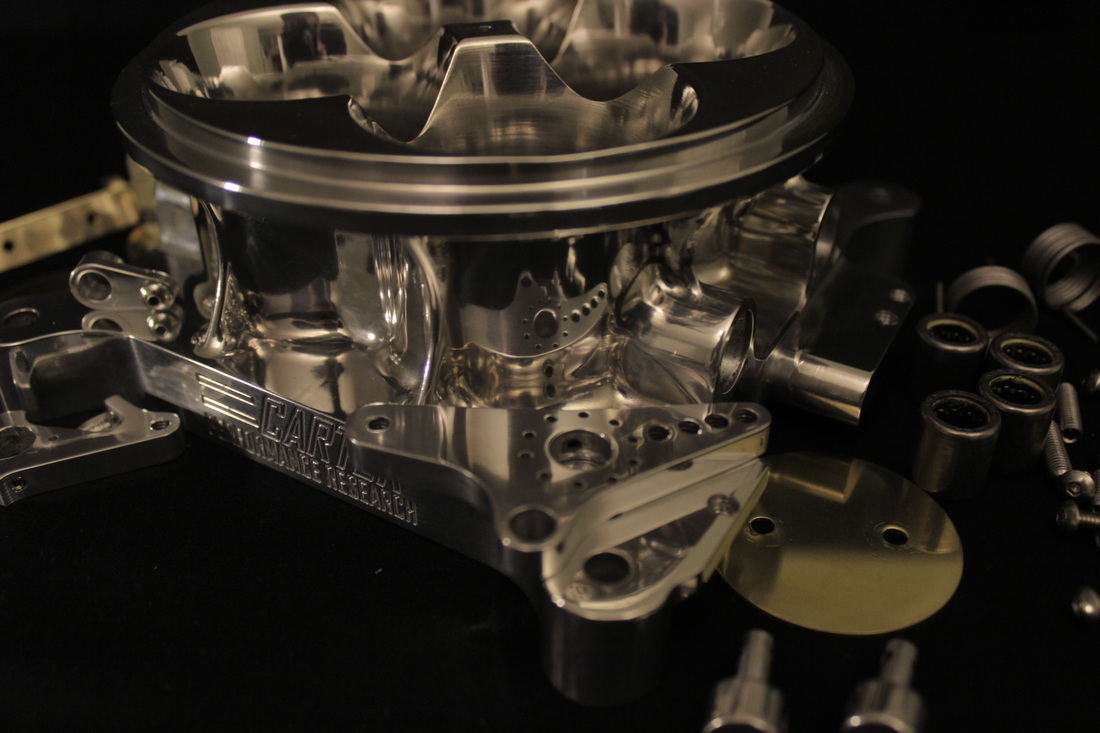

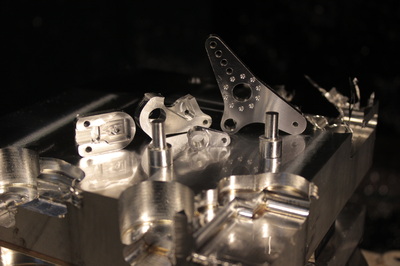

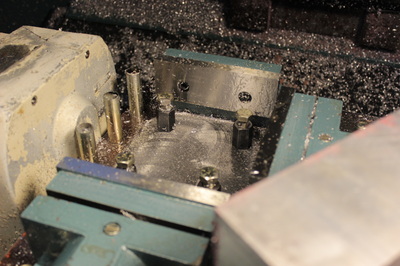

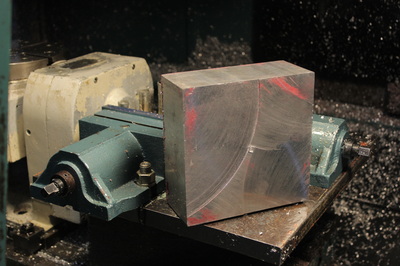

Today I machined serial #002. It will be the first one offered for sale after polishing, assembly, and cycle testing on the test stand.

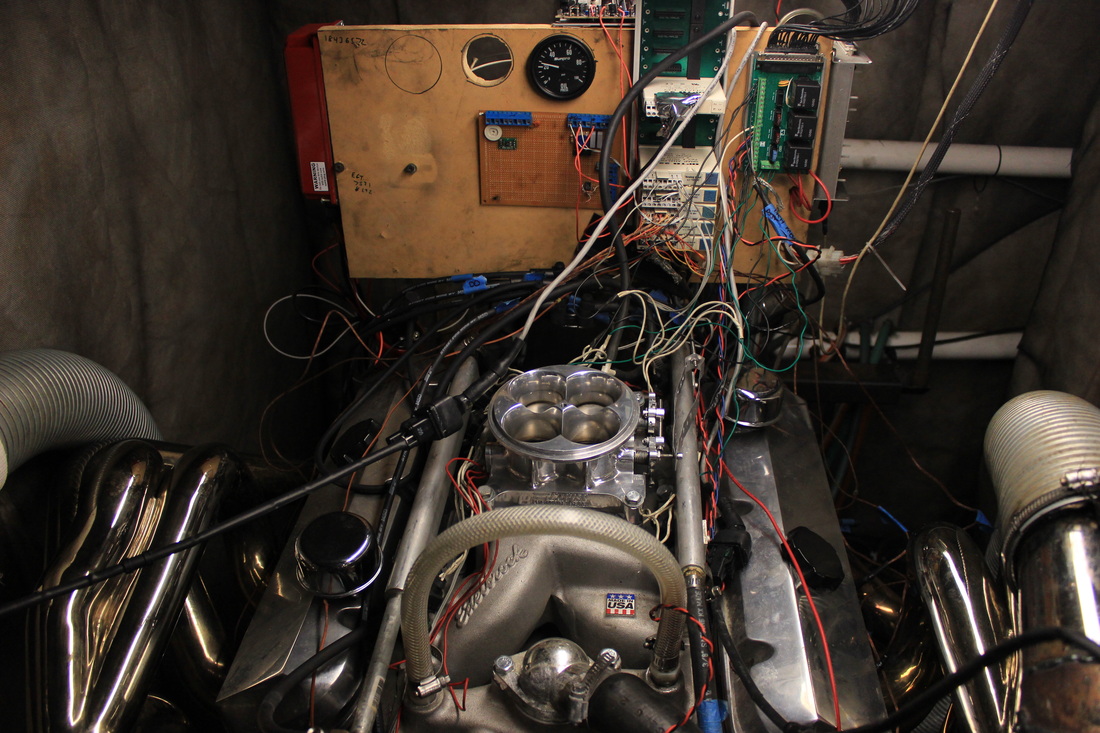

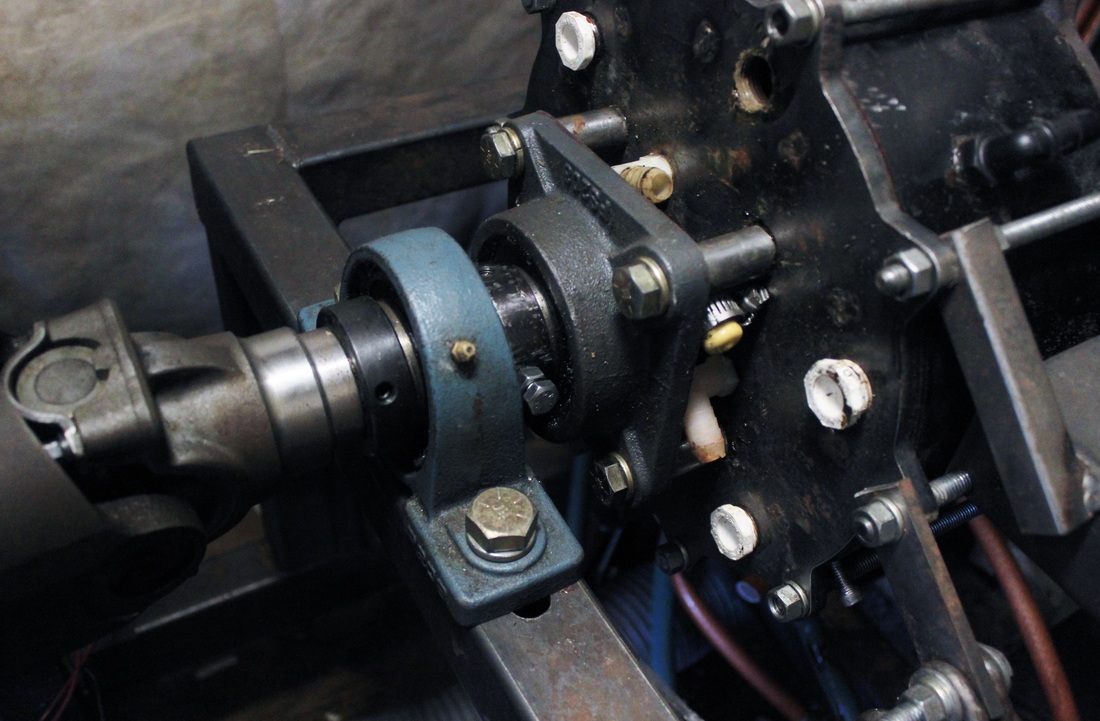

I nearly destroyed my prototype water brake in a dyno session recently. I've learned a lot from the brake, but very little of its design will be carried to the next version. The next will be machined rather than fabricated and will be "uncrashable". It's back together now with a few improvements.  Bent stator fins. Bent stator fins. The brake was designed with high volume to allow testing without huge pumps. It was able to make short tests of up to 500 hp off two garden hoses in the driveway. All the ports are for studying flow inside the brake. It's now housed in a sound dampened cell with a 200 gpm pump, water tanks, and a huge purpose built muffler system. It starts with an 80 gallon, three chamber muffler that flows into a 40 gallon glass pack, and then into a 2' X 4' X 16' fiberglass lined stack. I don't think the neighbors even know there's a dyno. |

AuthorKevin Carter Archives

March 2016

Categories |

RSS Feed

RSS Feed